ANOTHER SHOWCASE IS HERE!

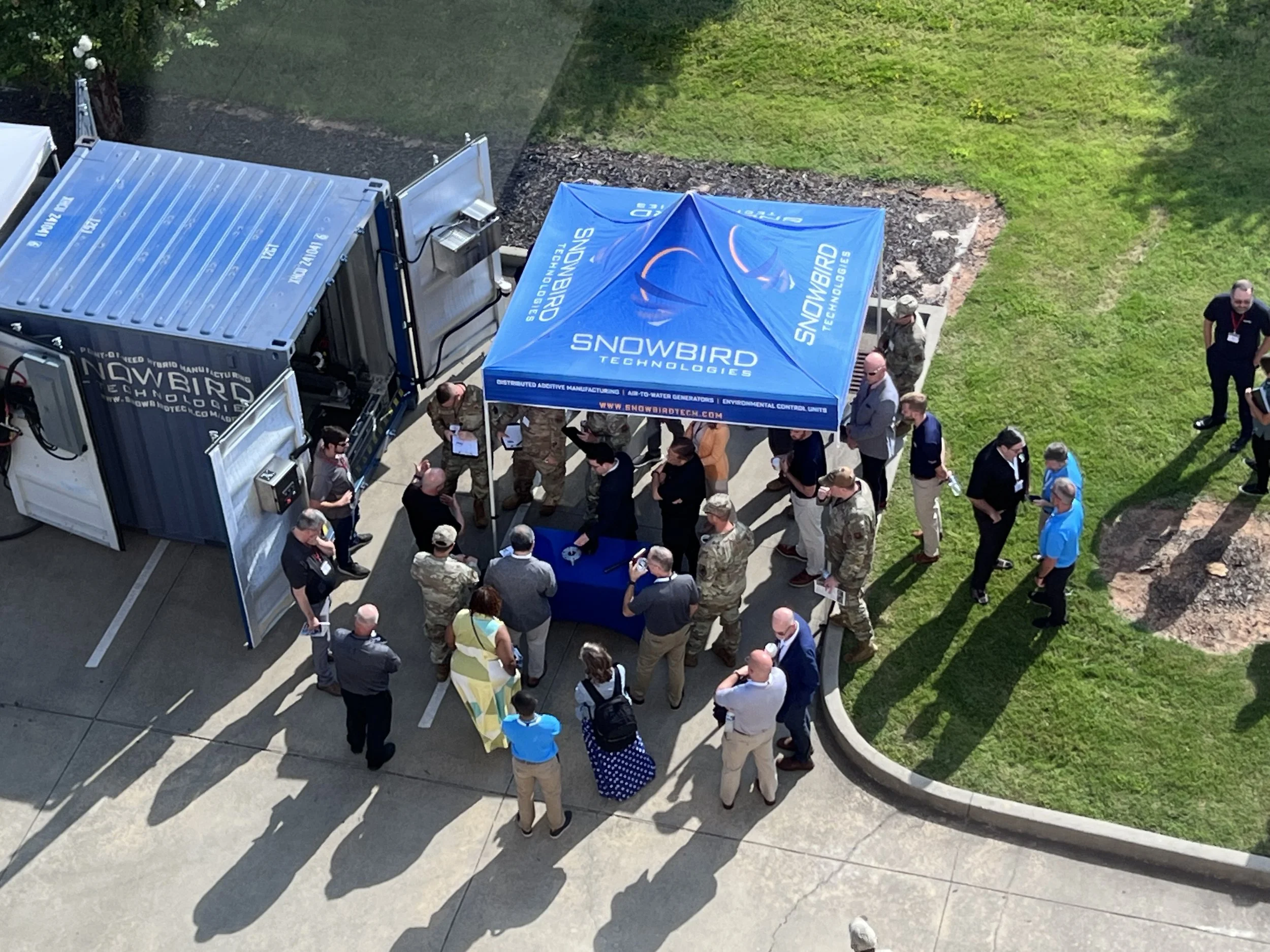

Air Force Global Strike Command (AFGSC) has partnered with SBCC to bring the best strategic capabilities to warfighters by identifying commercial technology innovations aligned with our military’s needs and enabling faster procurement.

One way we do this is through the Commercial Capabilities Showcase - where we bring the people behind the tech to Bossier City, LA for a two-day event. Applicant finalists are able to highlight their emerging technology to key decision makers who control up to

$3M in funding identified for use towards solutions demonstrated during the Showcase.

This year’s Mission Areas include topics co-sponsored by AF Air Mobility Command and AF Rapid Sustainment Office.

This is MORE than just a pitch event. It goes beyond demonstrations to create structured engagement opportunities helping companies and military better understand capability alignment, readiness considerations, and pathways for continued dialogue.

-

Purpose / Operational Context:

AFGSC seeks quantum‑enabled sensing approaches to enhance situational awareness and decision confidence in dense, cluttered, and denied environments where traditional sensing is degraded.

Future conflicts are expected to feature heavy vegetation, complex terrain, subterranean infrastructure, and adversary concealment and dispersion that challenge line‑of‑sight sensors (EO/IR, radar, LiDAR).

———

Scope of Interest:

Focus on quantum sensing applications beyond Positioning, Navigation, and Timing (PNT), distinct from ongoing quantum inertial and timing efforts in industry and across the DoW.

Interest in applications that expand the use of recognized quantum detection modalities and equipment (e.g., magnetic, gravitational, inertial, or timing‑based sensors) into sensing roles beyond traditional PNT, including environmental, structural, or anomaly‑focused use cases.

Applications that present technology solutions for novel quantum detection modalities or new use cases for existing modalities are also encouraged, particularly where they enable detection of subtle physical anomalies or environmental perturbations relevant to ISR and decision support.

All applications should demonstrate viability in environments where analogous conventional sensing methods would be denied or degraded (e.g., LiDAR in dense forests or heavy fog, EO/IR under canopy or in subterranean settings).

Additional interest in map‑referenced anomaly detection: interpreting measured fields or signals against reference models or baseline “maps” to reveal concealed activity, infrastructure, or changes over time, not just platform position.

———

Desired Concepts and Demonstrations

Quantum‑enabled sensing that augments or partially replaces current ISR architecture, or serves as stand alone ISR architecture replacement.

Quantifiable outputs or data representations suitable for fusion alongside existing ISR modalities within current COPs, C2 displays, and single‑pane‑of‑glass operational views.

Approaches that improve operator understanding (cueing, confidence, anomaly identification)

Use cases in land‑based or subterranean environments where line‑of‑sight sensors face physical limits (canopy, terrain, concealment).

Clear articulation of performance, maturity, risks, limitations, and integration considerations (data formats, interfaces, SWaP).

AFGSC seeks to better understand the operational relevance, limits, and decision value of emerging quantum sensing approaches and how quantum-enabled sensing can enhance decision advantage in future operational environments.

-

The Department of the Air Force is moving towards electrification of Support Equipment and Vehicles to improve operational efficiency, resilience, and sustainability. While SAF/IE and AFRL/RX are developing charging solutions for in-garrison operations, there is currently no integrated, deployable charging capability to support expeditionary environments. Specifically, a critical gap exists in the ability to interface existing deployable power sources—such as internal combustion generators and alternative energy systems—with electrified support equipment and vehicles. This gap limits operational flexibility, energy resilience, and effective use of energy storage in deployed settings, highlighting the need for a scalable, deployable charging solution.

Scope of the Problem: This effort is not about electrifying existing ground support equipment (GSE); rather, it addresses the means to support electrified equipment once fielded. The demand signal is driven by the introduction of electrified support equipment now and in the future. Existing deployed power sources (e.g., MEP or flightline generators, typically JP-8 fueled) already provide power. This is fundamentally an interface and energy management problem.

Power and Energy Considerations: There is a desire for the system to store energy and discharge it as needed, rather than operate solely as a pass-through from generator to equipment. Unlike garrison solutions which assume grid connectivity, deployed environments rely on MEP and flightline generators, creating challenges in efficiently converting and delivering power for charging electrified GSE.

Transportation Considerations: Solution should be air transportable (C-17/C-130) and should fit on a single pallet and include wheels or a skid.

Environmental and Operating Conditions: Must operate within MIL-STD-810 temperature extremes (approximately -60°F to +140°F). No emissions or environmental restrictions are imposed beyond airlift constraints related to energy storage type. The system is expected to operate outdoors only.

Energy Source Agnosticism: Power generation is out of scope. The solution must be energy-source agnostic, capable of accepting power from MEP or flightline generators (most likely, JP-8 fueled). Potential alternative sources include solar, hybrid fuel/renewables. The focus is on accepting input power and providing the correct output/interface for electrified support equipment.

Charging and Performance: Key attributes include voltage, wattage, amp-hours, duty cycle, deployment duration, and charges per day. The number of simultaneously charged assets cannot be predefined and will depend on total energy draw and industry-proposed solutions.

Technical Considerations and Flexibility: Voltage flexibility is critical. The system must accept multiple input voltages and provide appropriate outputs without requiring multiple adapters or “widgets.” A single, integrated solution should handle all necessary power conversions. Some degree of energy storage is desired, both for efficiency and for implicit redundancy, allowing the system to act as a power source if the primary input is unavailable.

-

AFGSC in coordination with RSO, seeks innovative advanced manufacturing (AM) solutions to enhance the resilience, scalability, and sustainment of weapons, decoys, and expendable countermeasure systems during wartime operations. In high-tempo conflict scenarios, supply chains for weapons components/subassemblies may be disrupted. The inability to rapidly replace or regenerate critical components directly threatens sustained munitions delivery and mission readiness.

This topic focuses on leveraging advanced manufacturing technologies to enable adaptable production of weapon system components/hardware. Solutions should improve AF’s ability to maintain weapons availability in response to wartime demand, while maintaining required safety, quality, and certification standards. The shared interest reflects the need to align weapons sustainment with rapid, scalable manufacturing pathways that can transition quickly from demonstration to the field.

Proposed solutions should address one or more of the following areas:

Critical Component Manufacturing: Demonstrate the ability to produce mission-critical weapon and munitions components (e.g., casings, fuses, brackets, housings, tooling, or support hardware) using metallic, polymer, or composite advanced manufacturing processes.

Of particular interest is the proposed solution’s ability to address requirements of air launched weapons (all up rounds) functional areas: Airframe/structure, Warhead (inclusive of fuzing), Propulsion, Guidance

Decoys and Expendable Countermeasures: Describe how the solution enables rapid, scalable production of decoys and expendable countermeasures intended for deception, survivability enhancement, or cost-imposition strategies. Solutions should emphasize manufacturability at scale, affordability, and adaptability to evolving threat environments.

Scalability: Explain how solution would scale manufacturing capacity during wartime. Discussion should highlight approaches to distributed manufacturing, throughput, and workforce size and training. Address any environmental constraints and requirements, support and post processing equipment for full operational capability, and ability to scale at varying distance operating locations.

Quality, Safety, and Certification: Address in-process methods to ensure parts meet safety, reliability, and performance requirements appropriate for weapons applications. Discuss pathways to qualification, certification, or risk-informed use during contingency operations. Address how the in-process data will be used in conjunction with other data (material performance, NDE, qualification data) to demonstrate transferability to producers.

Digital Thread and Cybersecurity: Describe integration with secure digital engineering environments, including protection of technical data, configuration control, and traceability from design through production and fielding.

Transition: Provide transition approach from demonstration to operational use, including timelines, dependencies, and potential integration with existing AF processes.

-

AFGSC and RSO seek solutions to drive change towards speed, flexibility, and industrial base revitalization mandated by the national defense strategy by addressing insufficient standards for Additive Manufacturing (AM). The final goal is to establish national standards that unlock on-demand production and create an agile and aligned industrial base. This showcase seeks solutions that will address a principal barrier for the adoption of national AM standard, the absence of a printer-agnostic, material-based certification and acceptance framework allowing AM parts to be approved and used at scale.

___Today’s approval processes are typically machine/program specific, requiring repeated qualification efforts each time a part is produced on a different AM machine. This constrains scalability and undermines value of AM during surge or contingency operations. Having a robust, standardized, and transferable method for qualifying AM processes across systems and distance will lower entry barriers for new vendors, expand competition, and secure the domestic AM supply chain alongside expanding partnerships in WAM to enable a joint network of Organic and Defense Industrial Base vendors.

___This topic is not seeking new manufacturing hardware or production capacity. Instead, it focuses on the decision, certification, and acceptance processes required to allow parts printed on different machines but using the same qualified material system—to be evaluated, approved, and released for use with appropriate confidence and risk management.

___Topic is not seeking new manufacturing hardware or production capacity. Instead, it focuses on decision, certification, and acceptance processes required to allow parts printed on different machines but using the same qualified material system—to be evaluated, approved & released for use with appropriate confidence & risk management.

___Proposed solutions should address one or more of the following focus areas:

Material-Centric Acceptance Models: Define certification constructs that anchor approval to material systems and process envelopes rather than individual printers, enabling broader reuse and scalability across heterogeneous AM platforms. To be considered your approach should be valid across all part features (thin wall features, sparse builds, large cross sections, etc.).

Digital Evidence Packages: Describe how: your approach will collect build data, inspection results, and process controls; how your approach will correlate collected data to material and part properties; and how the collected data and property correlations will be compiled into standardized, auditable evidence packages to support rapid approval by engineering, sustainment, or airworthiness authorities. An effective application should define what initial testing and evaluation standards your approach will use to develop certification algorithms (eg direct measurement, multi-scale modeling, ICME) based on build data and how it will then implement those data and results to nondestructive evaluation using in-situ or ex-situ inspection. Where possible, describe how the data provided within this package and testing results supports the intent of data requirements stipulated within FSB-25-01, EZ-SB-13, EZ-SB-19, and the structural integrity programs (Mil-Std-1587, Mil-Std-1798, etc.) to facilitate airworthiness certification.

Data Consistency and Transferability: Describe what level of material data (S-Basis, C&D-Basis, Fatigue Performance) is required for this framework to succeed. Describe how data will be shared among systems and how consistency of data collection, data providence, and sharing will be ensured across a wide network of distributed, heterogenous AM systems.

Risk-Informed Use Categorization: Propose tiered acceptance pathways that align part criticality with approval rigor (e.g., non-critical, mission-support, safety-critical), supporting faster decisions where risk permits based on the data collected in the digital evidence packages and use categories.

Governance Alignment: Address how framework integrates with existing Air Force and DoD roles, responsibilities, and approval chains.

Scalability: Demonstrate how framework enables reuse of data collected across programs, parts, and locations—reducing redundant qualification effort and accelerating enterprise-level adoption. Explain necessary process controls and expertise to successfully implement the framework and maintain repeatability/stability.

Integration: Describe how your proposed approach is integrated on AM platforms, with what platforms it is compatible, and what if any additional equipment or manpower will be required during operation and collection. Demonstrate transition from material level performance to part level performance using the acceptance framework alongside any relevant in-situ and ex-situ data.

Transition and Adoption Path: Outline how the proposed framework could be piloted, refined, and adopted within existing sustainment and logistics workflows, including training and change-management considerations. Address the TRL of your technology with specific focus on readiness to implement with above certifications using any relevant method.

Solutions that clearly separate certification logic from printer hardware, enable faster decision-making, and support enterprise-level reuse are strongly encouraged

-

Survivability in Compressed Standoff Environments for Near‑Term Fielding Large aircraft across Air Force Global Strike Command (AFGSC) and Air Mobility Command (AMC) are increasingly required to operate inside or near the threat envelopes of modern integrated air defense systems (IADS). These environments feature faster, more numerous, and networked threats that outpace the design assumptions of existing defensive systems. As adversary sensing and engagement ranges expand, traditional standoff distances are compressed, creating distinct but converging survivability challenges for low‑observable bombers (B‑2/B‑21), legacy non‑LO bombers (B‑52/B‑1), and AMC mobility aircraft (C-130, C‑17, C‑5, KC‑135, KC‑46).

The Problem: Current large‑aircraft defensive architectures cannot meet the sensing fidelity, warning timelines, threat characterization, or adaptive countermeasure performance required for survival in contested and semi‑contested environments.

LO platforms face emerging detection modalities (multi‑static radars, passive RF, IRST networks) that erode traditional advantages.

Legacy bombers face acute vulnerability as compressed standoff eliminates maneuver and EW‑based survivability tactics.

Mobility aircraft, historically reliant on sanctuary and routing, now face elevated risk as global IADS coverage expands and maneuver space collapses.

The result is a fleet‑wide survivability gap driven by the widening mismatch between threat evolution and defensive modernization timelines.

Industry Need: Industry is sought to deliver near‑term, platform‑agnostic, and threat‑agnostic survivability solutions that:

Provide improved detection, identification, and cueing across a global, multi‑domain threat spectrum

Enable rapid, adaptive, and effective countermeasures against advanced, networked, and time‑compressed engagements

Address the differing signatures, mission profiles, and integration constraints of LO bombers, legacy bombers, and AMC mobility aircraft

Integrate through open systems architectures and modular interfaces to support multi‑platform fielding

Minimize size, weight, power, and cooling (SWaPC) impacts to enable broad fleet adoption

Support accelerated fielding timelines, scalable integration pathways, and rapid modernization cycles

These solutions should restore operational flexibility for mobility and strike forces by enabling large aircraft to survive and operate effectively in compressed standoff environments against rapidly advancing IADS threats.

2026 MISSION FOCUS TOPICS

Need to know more? Join our live AMA Webinars!

Chat with our Subject Matter Experts and past Panel Judges at one of three live sessions. We’re answering all your burning questions, deep diving into topic areas, giving hot tips on application formats, and more! Replays will be posted shortly after.

NEXT WEBINAR: 3 FEB @ 1:55pm CST

WHY APPLY?

1. Engage with Government Stakeholders

Tailored interactions with personnel responsible for shaping priorities and understanding operational requirements.

2. Signal Relevance to Defense Needs

Selection into the Showcase indicates alignment with mission-relevant topics and provides visibility with key government leaders.

3. Gain Clear Insight on Alignment & Readiness

Understand where your capabilities intersect with Major Command priorities and what considerations influence longer-term engagement.

4. Build Pathways for Continued Engagement

Use the event as a steppingstone to accelerate conversations, bypass the typical multiyear timeline of traditional channels, and continue productive follow-on evaluations informed by real feedback and shared goals.

5. Funding Ready to Advance Technology

AFGSC has set aside $3M* for potential follow-on work with Showcase Finalists.

*Funding is not an immediate award, but distributed after agreed path forward and signed contract with AFGSC per company.

6. SBCC x Plug and Play

SBCC has partnered with Plug & Play - a premier venture capitalist (VC) and Accelerator for this year’s Showcase that will expand support for finalists—enhancing readiness and strengthening engagement ahead of the in-person event.

More details to come!

plus+

KEYNOTE SPEAKERS

COLLIDER SOCIAL (13 MAY )

WHO SHOULD APPLY?

The 2026 Showcase is best suited for companies who:

Are developing technologies, products, or services with potential warfighter relevance

Are ready for serious, mission-focused dialogue

Want clarity on where their solution fits and what’s required to move forward

Are interested in longer-term engagement and relationship building within the US military ecosystem

Companies at various stages of maturity are encouraged to apply.

HOW SELECTION WORKS

Applications are reviewed by a panel of industry Subject Matter Experts (SMEs) and Department of War stakeholders who identify which technologies align best with the Showcase focus areas and priorities.

All applicants will be informed whether or not they have been selected as a Finalist to attend the In-person Showcase event MAY 13-14.

All applicants will receive their rubric ratings, comments, and (possible) follow up conversations/contact with interested parties.

Air Force Global Strike Command provides strategic deterrence, global strike capability and combat support to US Strategic Command (USSTRATCOM) and other geographic combatant commands. As part of its mission, AFGSC partners with industry to explore commercial innovations that can strengthen readiness and operational performance.

SBCC is a trusted partner and resource for the Department of Defense, supporting the integration of innovative commercial technology and enabling structured engagement between government and industry.

About AFGSC & SBCC

SBCC holds a contract with Air Force Global Strike Command (AFGSC) to support rapid acquisition decision-making through commercial engagement and integration. As part of this contract, SBCC is responsible for technology scouting and conducting due diligence on emerging technologies. However, SBCC does not control access to AFGSC, nor do government contracting regulations permit it to do so. Any individual or company can directly engage with AFGSC, presenting initiatives they believe align with its mission and seeking support for SBIR or other contracts—without any requirement to interact with SBCC.